For manufacturers, quality isn’t just a checkpoint — it’s the backbone of brand reputation, regulatory compliance, and operational efficiency. But what if your most important insights are hidden in images, drawings, PDFs, and free-text reports?

In his latest feature in Automation World, Stellar COO Zach Linder unpacks how forward-thinking manufacturers are using AI to unlock quality data trapped in legacy formats—and in doing so, transform processes from design to compliance.

Read the full article on Automation World →

What You’ll Learn:

-

Where critical quality data lives (hint: it’s not always in your ERP)

-

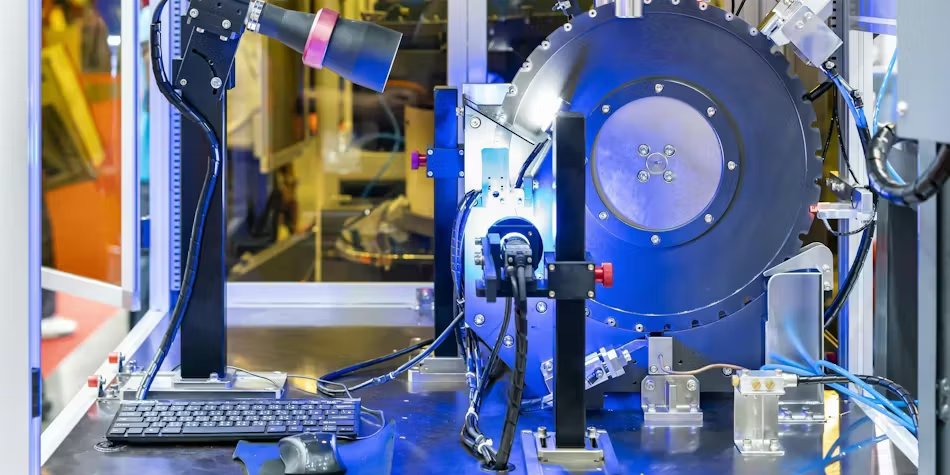

How manufacturers are using Vision AI and document intelligence to surface hidden insights

-

Why AI-powered tools are helping engineers, quality leads, and compliance teams collaborate faster and smarter

-

The real-world outcomes leading teams are already seeing — from faster audits to fewer product defects

Whether you’re in automotive, electronics, med device, or contract manufacturing, the use cases are practical and repeatable — not just flashy prototypes.

Why It Matters:

AI in manufacturing isn’t about replacing experts — it’s about giving them superpowers. By letting machines handle document parsing, anomaly detection, and cross-referencing at scale, human teams can focus on the tough decisions only they can make.

And with the right governance and integration, these systems are both reliable and auditable — two things every quality team wants to hear.

👉 If you’re exploring AI for quality and compliance, or just want to see what’s possible with today’s tools, this is worth a read.